Taking Panes: Conserving the Senate foyer’s stained-glass ceiling

In February 2019, the Senate moved to the Senate of Canada Building, a former train station built in 1912. The Senate will occupy this temporary location while Parliament’s Centre Block — the Senate’s permanent home — is rehabilitated.

Although Centre Block is shuttered for rehabilitation work, Canadians can still experience its art and architecture through the Senate’s immersive virtual tour.

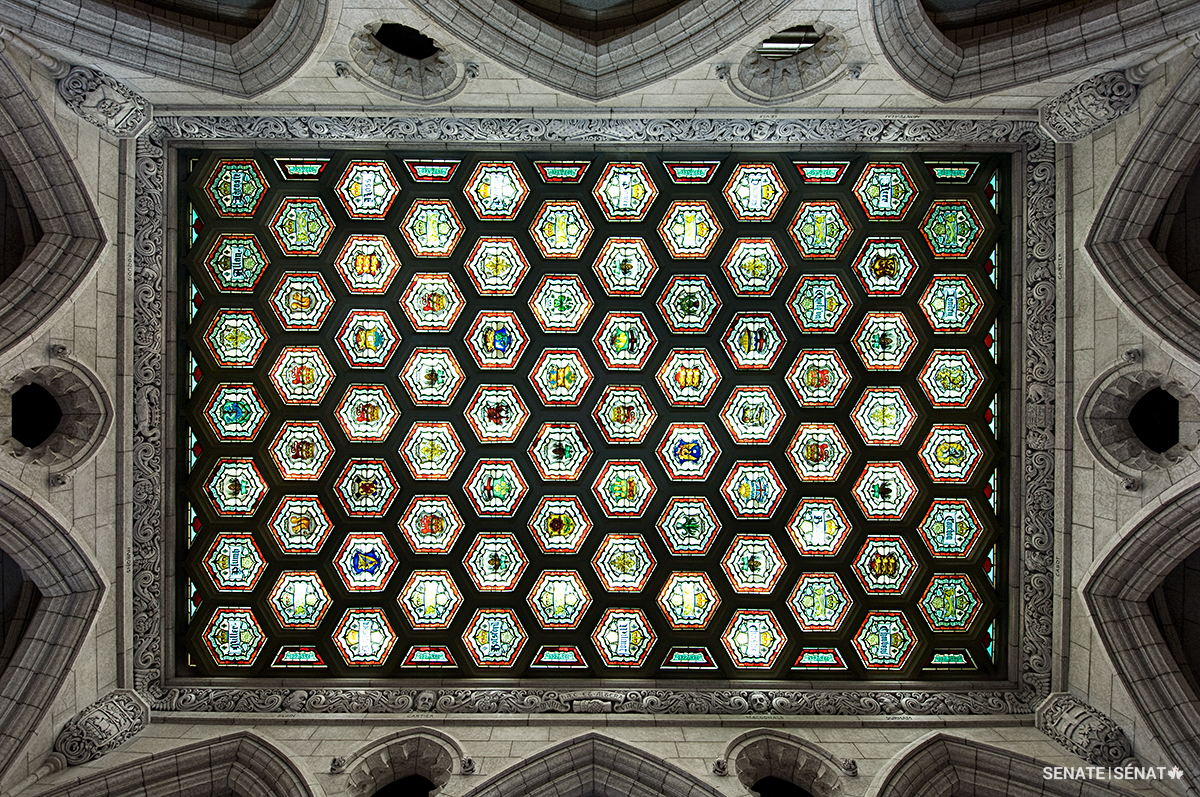

A gentle glow, like sunlight in a forest clearing, once greeted visitors to the Senate foyer in Centre Block. The source? A coffered ceiling the size of a tennis court, made up of dozens of stained-glass windows.

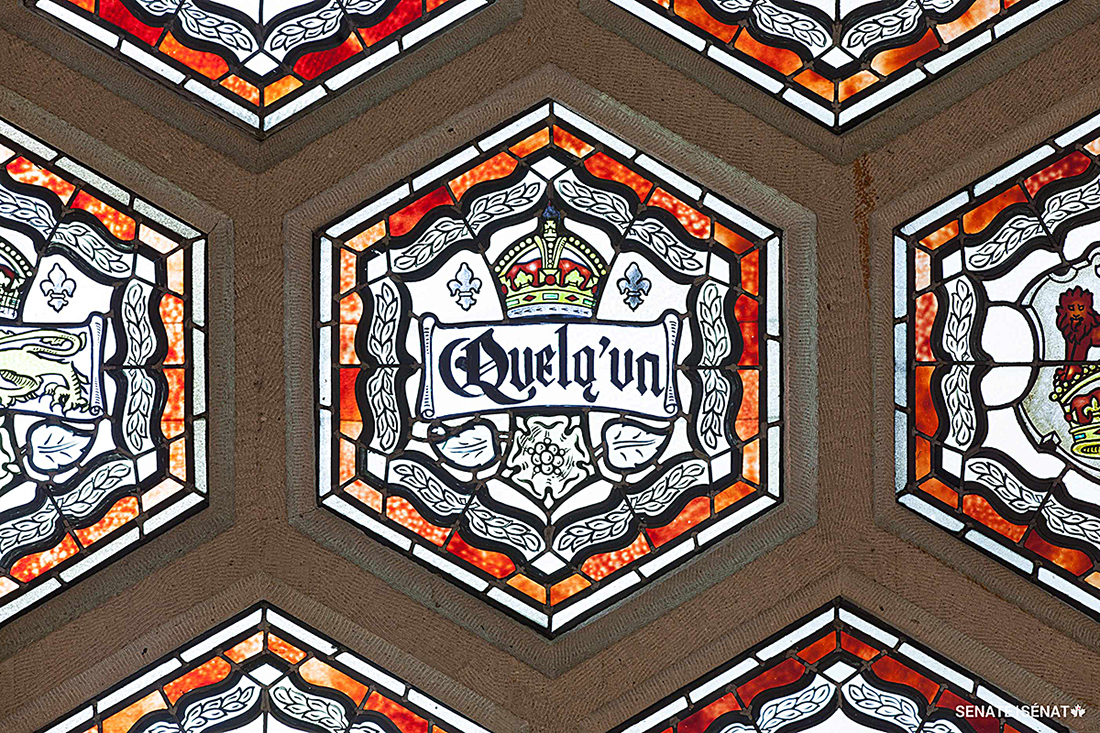

Designed and installed more than a century ago, it features heraldic emblems referencing the British and French cultures that helped create the Dominion of Canada. Interspersed among these devices — including fleurs-de-lis, shamrocks, lions, unicorns and dragons — are the names of the first 17 speakers of the Senate, along with their respective provincial coats-of-arms. The whole assembly floats within an intricate Tudor-style tracery, constructed of reinforced concrete textured to resemble limestone.

The stained-glass panels are among thousands of works of art that are being removed, repaired and put into storage as part of the rehabilitation of Centre Block, the largest heritage restoration project in Canada’s history. Conservation experts at Westport, Ontario-based Traditional Glassworks refurbished the ceiling panels in the spring of 2023.

The panels form part of a sophisticated illumination system, called a laylight, that combines a flat glass canopy with an auditorium-sized lightwell behind, where natural illumination, flooding in through a skylight, is boosted by reflector units. A catwalk encircles the entire space, allowing access for maintenance.

Centre Block’s Senate foyer is illuminated by an enormous stained-glass ceiling designed by architect John A. Pearson. The ceiling was manufactured by Toronto’s N.T. Lyon Company, which also created the stained-glass ceiling in the House of Commons foyer.

Centre Block’s Senate foyer is illuminated by an enormous stained-glass ceiling designed by architect John A. Pearson. The ceiling was manufactured by Toronto’s N.T. Lyon Company, which also created the stained-glass ceiling in the House of Commons foyer.

A fragile, century-old treasure

The ceiling was manufactured by Toronto’s N.T. Lyon Company and installed in the early 1920s as Centre Block took shape on top of the foundations of its 1866 predecessor.

The company’s founder, Nathaniel Theodore Lyon, immigrated to Canada from Ireland in the 1860s to join Toronto’s McCausland Studio, North America’s first and largest stained-glass manufacturer. Lyon went out on his own in 1881 and quickly grew his business into Toronto’s second-largest stained-glass production house.

For six decades, it turned out thousands of windows for churches, banks and government buildings across the country.

Traditional Glassworks is one of the few studios in the country with the experience and know-how to handle this fragile, century-old treasure. It was incorporated in 2015 by glass artist Mark Thompson, a graduate of the Ontario College of Art and Design.

The ceiling’s 105 panels — each one comprised of dozens of coloured, hand-painted panes of glass — needed to be removed from the concrete lattice supporting them, taken apart, refurbished, then soldered back together.

The intervention came at just the right time: the 100-year-old lead that holds the panes in place had deteriorated to the point of being a safety concern.

“It was riddled with small fissures and covered with light lead oxidation,” Mr. Thompson said. “This is lead’s version of rust. It can be toxic if handled directly.”

A painstaking process

The restoration process started with disassembling the entire window, piece by piece.

“The lead is severely oxidized and quite dangerous,” Mr. Thompson pointed out. “We take the windows apart underwater, so nothing becomes airborne.”

“We then lay each pane out in its corresponding position, so we don’t have a puzzle to put back together.”

Some panes were damaged beyond repair and had to be replaced outright. In this case, an artist recreated the original design using a special paint containing powdered glass. The panes were then fired for 24 hours at 650 °C.

“The colour completely fuses with the glass,” Mr. Thompson explained. “You can scratch it with a knife and it won’t come off.”

The next step was re-leading. Each strip of lead — called came — is shaped like an H in cross-section, with the glass slotting into its twin channels. Once the entire window was re-leaded, each joint was soldered.

Finally, a thick putty made of calcium carbonate, linseed oil and black pigment was applied over the entire window and worked deep into every corner to make the window airtight, waterproof and resistant to oxidization.

“We clean this emulsion off with a hog-hair brush. It leaves a dark, lustrous, water-repellant patina that completes the window beautifully,” Mr. Thompson said.

Traditional Glassworks will reinstall the ceiling when the Centre Block rehabilitation project nears completion. Removal and reinstallation are delicate and potentially dangerous procedures that require expert handling by specialists.

Mr. Thompson is grateful to have contributed to preserving one of Canada’s most iconic buildings.

“I grew up in Ottawa and any Canadian specialist would want to say they worked on the Parliament buildings,” he said. “It’s an honour and a huge responsibility to do it right.”

Conservator Udiya Swamy cleans the edges of a newly disassembled piece of glass.

Conservator Udiya Swamy cleans the edges of a newly disassembled piece of glass.

Conservator Tristan Adams reinforces a thin piece of glass with a clear, non-reflective backplate.

Conservator Tristan Adams reinforces a thin piece of glass with a clear, non-reflective backplate.

Each decorative panel is like an intricate jigsaw puzzle. Conservator Liam Fenton lays out the dozens of individual panes that make up a window exactly as they were originally.

Each decorative panel is like an intricate jigsaw puzzle. Conservator Liam Fenton lays out the dozens of individual panes that make up a window exactly as they were originally.

Conservator John Martin re-leads a window, joining pieces of glass together with strips of lead called came. The lead must be cut exactly — the tiniest gap can allow molten lead solder to seep through and crack the glass.

Conservator John Martin re-leads a window, joining pieces of glass together with strips of lead called came. The lead must be cut exactly — the tiniest gap can allow molten lead solder to seep through and crack the glass.

Each window is finished with a coating made of calcium carbonate, linseed oil and black pigment. Conservator Hayden Maynard works the thick putty into every joint, then scrubs the excess off with a hog-hair brush.

Each window is finished with a coating made of calcium carbonate, linseed oil and black pigment. Conservator Hayden Maynard works the thick putty into every joint, then scrubs the excess off with a hog-hair brush.